Due to our high level of expertise in filtering systems we are always looking for the best fitting options for you as our client. From the first contact to the startup of your implementation.

Made in GERMANY

Filter units for welding technology

Dust filters, filters systems as well as components for metal processing industries in cutting and welding.

Task force - Case Study

The client needs a solution for dedusting 5 workplaces and free those from metal and grinding dusts within the process. The pollutet air should be cleaned and either funneld via pipe-system to the outside or fed back to the working space.

HAINKE Solution

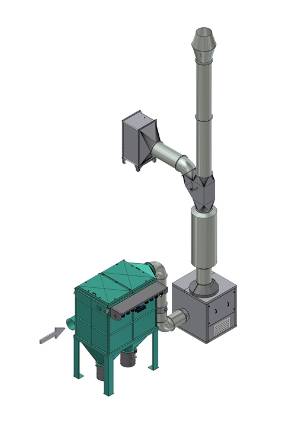

Each of the workplaces is equipped with extraction arms connected over to a fixed central pipesystem which takes the dust into cartridge filters.

Suction performance is safeguarded via a radial fan stored within a sound cover for noise reduction and all-wheather protection. Via a manual flap box within the exhaust pipe system the air can either be fed back to the production hall or led to the ouside. A duct silencer pipes down the noises.

Used air is discharged via deflector hood in accordance with the clean air regulation stipulated in the governmental TA -regulation.

HAINKE components

- housing Cartridge Filtering type FPG 40-12 = 128,00 m²

- radial fan type MXE 035-011830-00 - GR 360 (11,00 kW)

- noise absorption hood type H-HS 145-OB

- control cabinet type FPS 3000

- pipe system and exhaust tube DN 150

- flap box and policing filters type H-FK 1/2